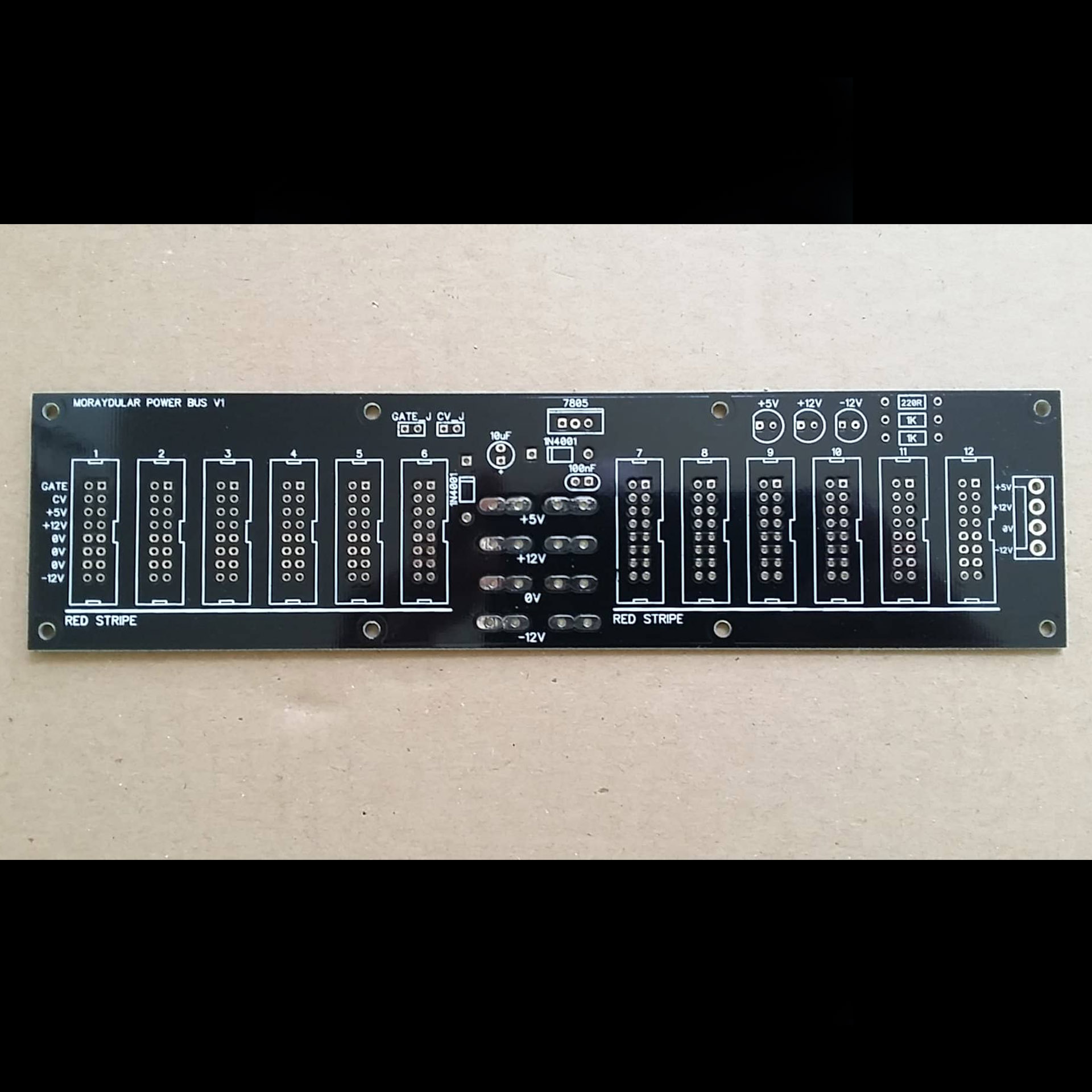

Description

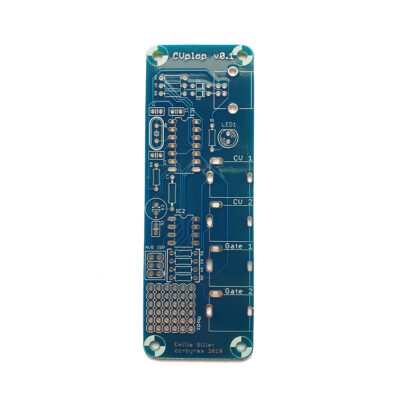

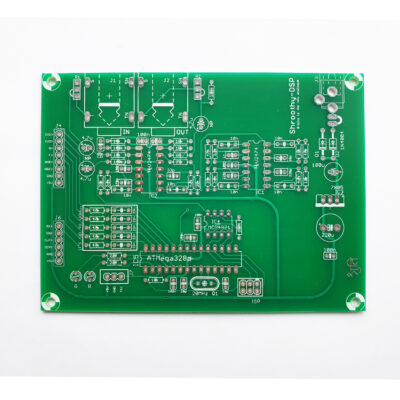

Populating the PCB should be relatively straightforward. Some notes:

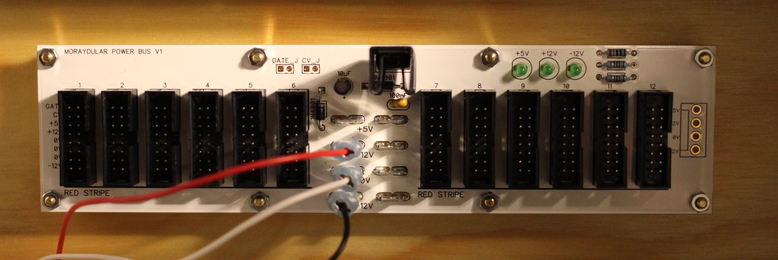

- The LED polarity follows standard convention: the short leg / cathode / notched side of LED goes where there’s a notch in the silkscreen.

- The pads for connectors have quite wide thermal reliefs, so soldering them may require some extra heat and patience. In particular, the -12V (bottom row) pins in ribbon connectors will take some warming up for the solder to flow properly.

- When using mounting tabs, you may want to solder them on both sides for extra sturdiness because it usually takes some force to detach the cables.

- If not building the +5V adapter, leave out parts as indicated in BOM below

When using onboard +5V in multiple bus board system, either build the regulator circuit for all boards and leave out +5V link cables or populate the regulator circuit for just one board and distribute +5V to all boards. Never link +5V rails of two boards together if they both already have their own +5V feeds.

Bill of Materials

For plain passive board:

- 12x 16-pin (2×8) 0.1″ shrouded box header (eg. Reichelt WSL 16G) OR unshrouded pin strip

- 6x PCB-mount Faston / Abiko style mounting tabs (eg. Reichelt FS-P 6,35)

- Alternative: 1x 4-pin 0.156″ PCB mount connector (MTA156, Molex KK .156)

- Or you can just solder the wires from PSU directly to the PCB

- 3x 3mm LEDs

- 3x Current limiting resistors according to LEDs you’ve chosen (2x 1K, 1x 220R as indicated on PCB silkscreen should be fine at least for normal red or green leds)

For +5V onboard regulation add the following:

- 1x 7805 voltage regulator

- Use a heatsink according to your planned current draw

- Pin-compatible DC-DCs such as OKI-78SR-5/1.5-W36-C should work and provide more current with better efficiency and no heatsink required, but currently untested

- 2x standard rectifier diodes, any of 1N4001…1N4007 will do

- 1x 10uF electrolytic capacitor, 16V or higher voltage rating

- 1x 100nF ceramic capacitor